At CR we work with the development and testing of electrochemical devices and biosensors. Together with an electrode manufacturer or with the selected electrodes, we develop and technically validate the technology.

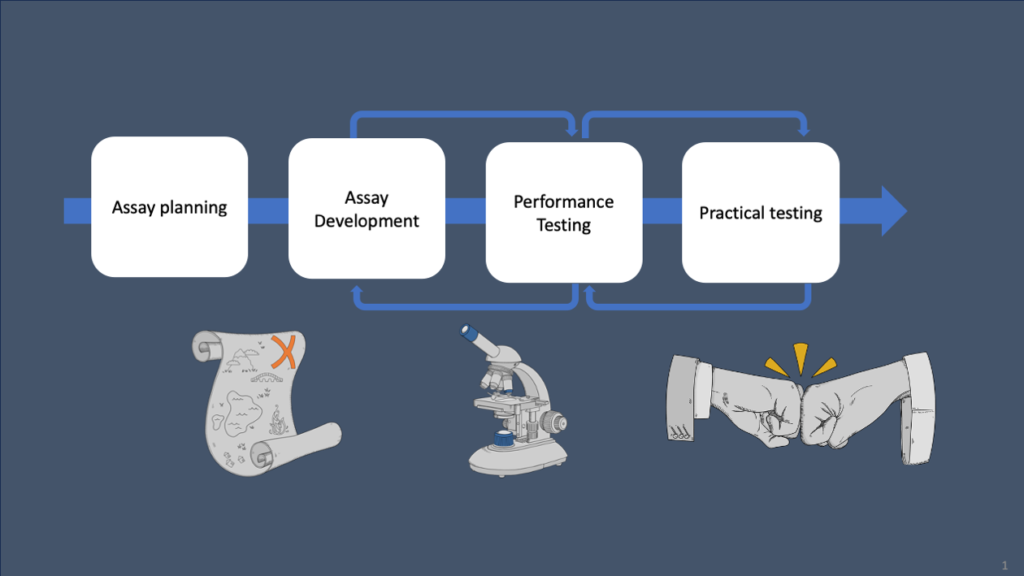

Assay planning

In the first phase we identify the recognition element (enzyme, antibody, aptamer or other) and the immobilization strategy. We consult on supportive material, fouling- and inhibitor strategy as well as practical techniques regarding deposition and analysis.

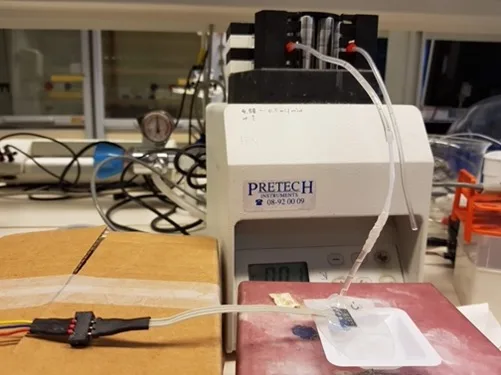

Here, the microfluidic set up for a glucose sensor is designed and tested.

Other earlier technical tests are to evaluate deposition methods and of course choice of elements to recognize and to be used for recognition.

Assay development and validation

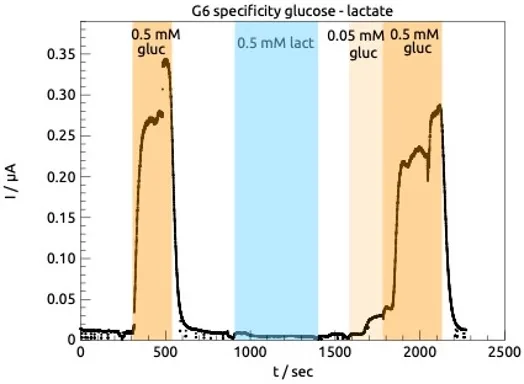

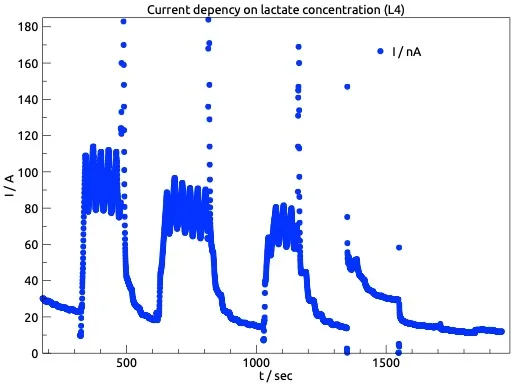

This phase entails the practical analytical electrochemistry with optimization of signal-to-noise ratio, tests for specificity and sensitivity and first stability tests. We also further optimize the deposition technique and look at solutions for very common interference problems. In this phase, it is valuable to work together with the electrode provider.

Close-to-real testing

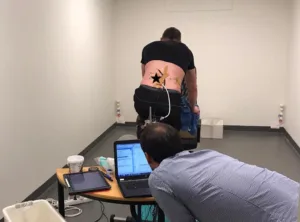

Before the true performance tests, the sensor is evaluated in so called close to real conditions. These have to be designed from case to case. In addition to what was tested in the previous step, focus is given to repeatability and reproducibility. Due to the more complex conditions, interference problems can be expected.

Performance testing, pre-clinical tests

In this fairly late stage, the sensor is tested in-operandi and the usage condition is as real as possible (depending on industry, regulatory and scale). The robustness of the sensor and the data is tested. Depending on the application, other aspects can be highlighted such as adhesion over time, corrosion of the material and leachables or migration to or from the device.

Cases

In addition to the below listed sensor-development tests, the knowledge have been used for other products. For example, deposition and immobilization is used by CR for a broad variation of clients and products. Bio-conjugation of “an element” to a particle or membrane is important beyond sensors and we have worked extensively with for example Alteco Medical on such work. The electro chemistry and analytical method development is also an area of expertise that of course is constantly developed and used elsewhere in CR projects, for example regarding stability, extractables and leachables. Material interactions with skin and surface behavior in general is explored for personal care as well as medical and filter fouling….

This is why CR can be an ultimate partner for sensor technology: the cross-business learnings and the holistic team-approach.

- Innovosense: we acted as a scientific peer and performed a first evaluation of the technology as well as practical test.

- Lumito: we consulted on assay development and performance testing.

- Undisclosed: understanding and problem solving for a colorimetric sensor.

- Dent2Health: Assay ideation and critical literature review for pre-diabetes tests using saliva as sampling matrix.

- Undisclosed: assay planning, development and performance testing.