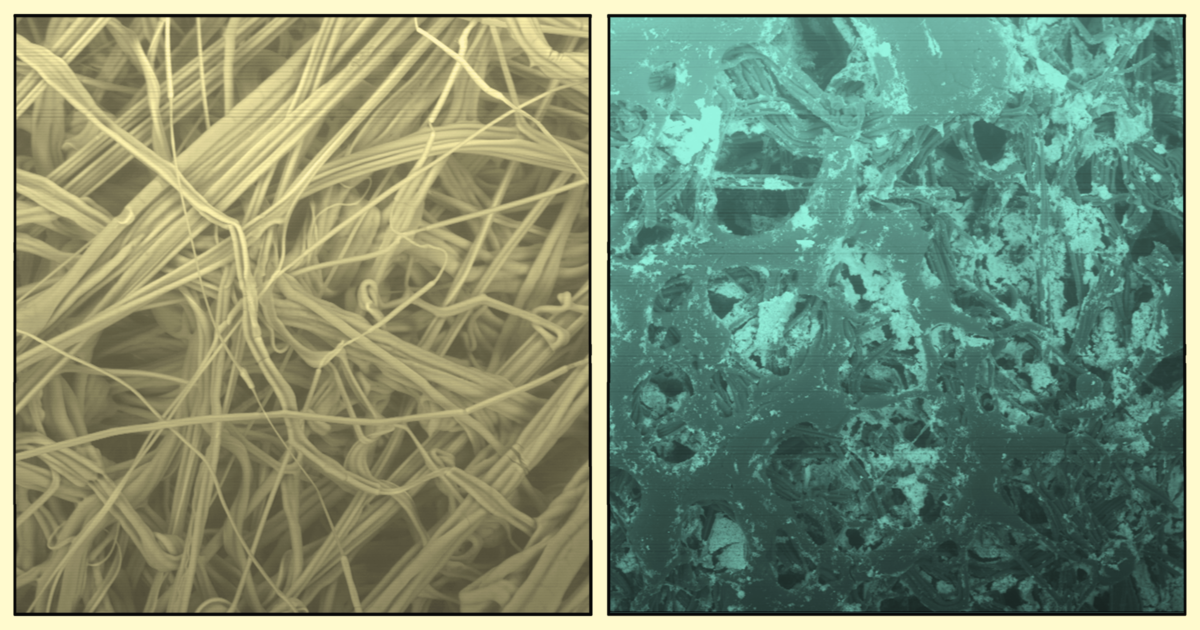

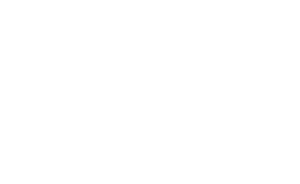

illustration by Maja Stenstam based on two electron microscope images of filters, fresh and clogged.

Filters are used in almost all production processes. They are used in manufacturing of pharmaceuticals as well as food products. They are used to ensure longer life expectancy of process infrastructure, reducing corrosion and biofilm formation. And sometimes, they are the life supporting product in itself, such as in dialysis or emergency sepsis care.

Contaminants are always retained and accumulated on the surface or interior of the filter, leading to a need of higher pressure to filter and eventually, the filter is no longer working. It is crucial to identify the root cause to the clogging and at CR we have tools to help.

When you think you know what fouls

In one such case, we received filters from the MAX IV laboratory, the very advanced synchrotron facility which is a national research infrastructure in Sweden. These filters were a part of their cooling water system, a system of vital importance both for operating their accelerators but also as in this case thermal stability for their X-ray optics. At MAX IV they had for some time experienced corrosion issues in these circuits and therefore approached us in order to make a detailed study on what was clogging the filters. Samples from different positions and cross-sections were analyzed using vpSEM-EDS, an electron microscope technique. With such images, information about the extent as well as the morphology and chemical elemental information of the fouling could be obtained and MAX IV engineers know for sure what their problem was.

When you do not know what fouls

In another case, the identity of the clogging-material was much less clear before analysis and to complicate it further, most probably a mix of several organic molecules. Here, we had to be the ones introducing a plausible hypothesis before embarking on any analytical quest. Based on our expertise in colloidal science, specifically surfactant and polymer interactions we could not only validate our hypothesis but also test different remedies, i.e. cleaning procedures to prolong the lifetime of the specific filter.

Working with us on your filter issues will help you to:

- get a better understanding of the performance of your filters

- identify key foulants

- find strategies for mitigation and longer lifetimes of your filters

Valuable filter analysis used by CR

Morphology and Physical properties

- SEM

- vpSEM

- Optical microscopy

- Contact angle

- Visual inspection and weight analysis

Physical properties of the coagulants and water/process stream

- Light- and xray scattering techniques

- Laser diffraction

- Microscopy

Chemical analysis

- SEM-EDS

- FTIR and Raman spectroscopy

- HPLC-UV/ELS/CAD/MS

- Raman microscopy

- XPS

- XRD

Model system verifications

- QCM-D

- Ellipsometry

- In-situ lab scale membrane models

- In-situ precipitation trials