Know your boundaries, control and push them

Process control for CR is built upon knowing better how ingredients and material interact and what the consequences of this is. We know that there are boundaries one need to have margins too and that the many forces in play can lead to abrupt and non-intuitive changes with process variables. This can however be understood, mapped out and controlled.

For clients within Process Control we have for example:

- optimized a bioconjugation protocol of peptide to substrate

- developed an alternative route for reduction of 1,4 dioxane in product

- developed alternative protocols to improve adhesion in laminated product

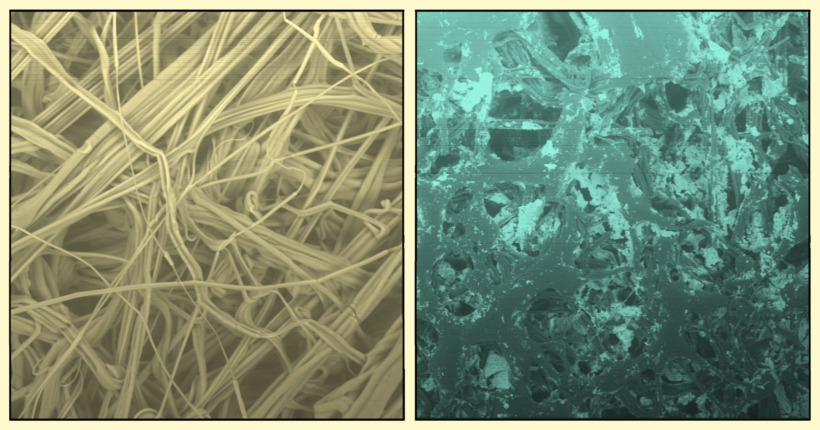

- investigated crystalline structures and annealing times for fibers

- changed order of unit processes to reach higher robustness

- developed in-line analytical methods

Examples of cases within “process control”

To know more about how such projects can be structured and in which areas we work, check the links below or contact any one in the team.